News

2023/3/15

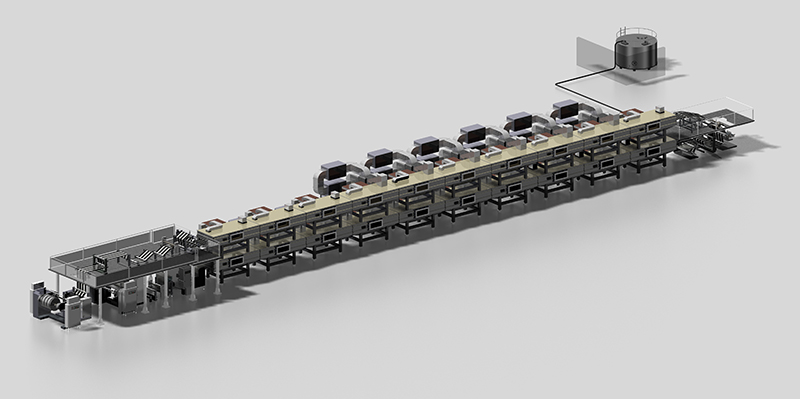

Development of an Eco-Friendly Coater for LiB Electrodes, 'Green Coater'

Toray Engineering Co., Ltd. (Tokyo, Japan) has developed an eco-friendly coater for secondary lithium ion battery (LiB) electrodes, Green Coater®, and will launch it next April.

Green Coater® is a device that coats electrode materials over base materials in the LiB electrode manufacturing process. A new highly efficient drying system that we developed can reduce energy consumption by about 25% compared to conventional machines.

To realize a carbon-neutral society, Toray Engineering will launch this eco-friendly Green Coater® and propose it to LiB manufacturers across the world. The target order volume is 1.5 billion yen in fiscal 2023 and 5 billion yen in fiscal 2026.

LiB electrodes are produced by applying coating fluid made by blending electrode materials and organic solvent to metal base materials in advance and drying it. Although hot-air drying, where LiB electrodes are dried with heated air, is commonly employed, the inside of the furnace must be constantly heated to a high temperature to control the concentration of organic solvent in the furnace below the explosion-proof standards(*) while taking in outside air for ventilation. Therefore, energy consumption in the electrode production process is said to account for about 45% of that in the whole LiB manufacturing process.

Toray Engineering has developed a proprietary drying system that circulates and reuses hot air in the dry furnace to reduce energy consumption in the LiB electrode manufacturing process ahead of our competitors. This technology integrates the dry furnace and the organic solvent collection unit into a single system to collect the solvent and circulate and reuse heat even though hot air used in the dry furnace went through exhaust treatment in solvent collection equipment outside the factory in the past. This circulation cycle makes it possible to minimize energy loss during solvent collection, eliminating the effects of phenomena such as liquefaction of organic solvent in the duct due to outside air, which were issues in conventional systems. In addition, energy consumption can be reduced by up to 55% compared to conventional manufacturing methods by optimizing the controlled concentration and circulation conditions in line with a recent relaxation of the controlled concentration regulation in the explosion-proof standards.

In addition, because Green Coater® circulates and reuses hot air, it is possible to simplify the air supply ducts for taking in outside air, exhaust air ducts for discharging used air to the atmosphere, and exhaust gas treatment equipment to reduce initial costs.

Demand for LiB is expected to increase sixfold or so compared with that in 2022 by 2030 due to factors such as the increasing percentage of electric cars. In this context, LiB manufacturers are aggressively making capital investments to increase their production capacity. We will address positive demand for equipment and develop and deploy manufacturing technologies with high environmental performance to contribute to the realization of a decarbonized society.

Toray Engineering will contribute to the realization of a carbon-neutral society and provide solutions for all kinds of manufacturing challenges by leveraging our technology, engineering expertise and know-how.

* Explosion-proof standards: Standards for preventing ignition of explosive gases such as organic solvents.

- Category

- Headline News