News

2024/1/24

Industrial cleaning - new technology leads to greater efficiency despite a shortage of staff

From May 14-17, 2024, the Fraunhofer Institute for Process Engineering and Packaging IVV will be exhibiting cyber-physical cleaning technology for quality-assured, efficient and resilient production processes at Interclean in Amsterdam, Hall 5, Stand 530. In the Robot Arena, visitors will also have the opportunity to find out how the cleaning robot with sensor-guided adaptive jet cleaner devel-oped by Fraunhofer IVV works.

© Fraunhofer IVV

In order to address quality risks in manual cleaning processes and the increasing challenge posed by the shortage of skilled workers, Fraunhofer IVV has developed innovative sensor technology and digital applications for adaptive cleaning processes.

Automation and repeatability - mobile cleaning robot detects, cleans and then documents cleanliness in hygiene-critical areas

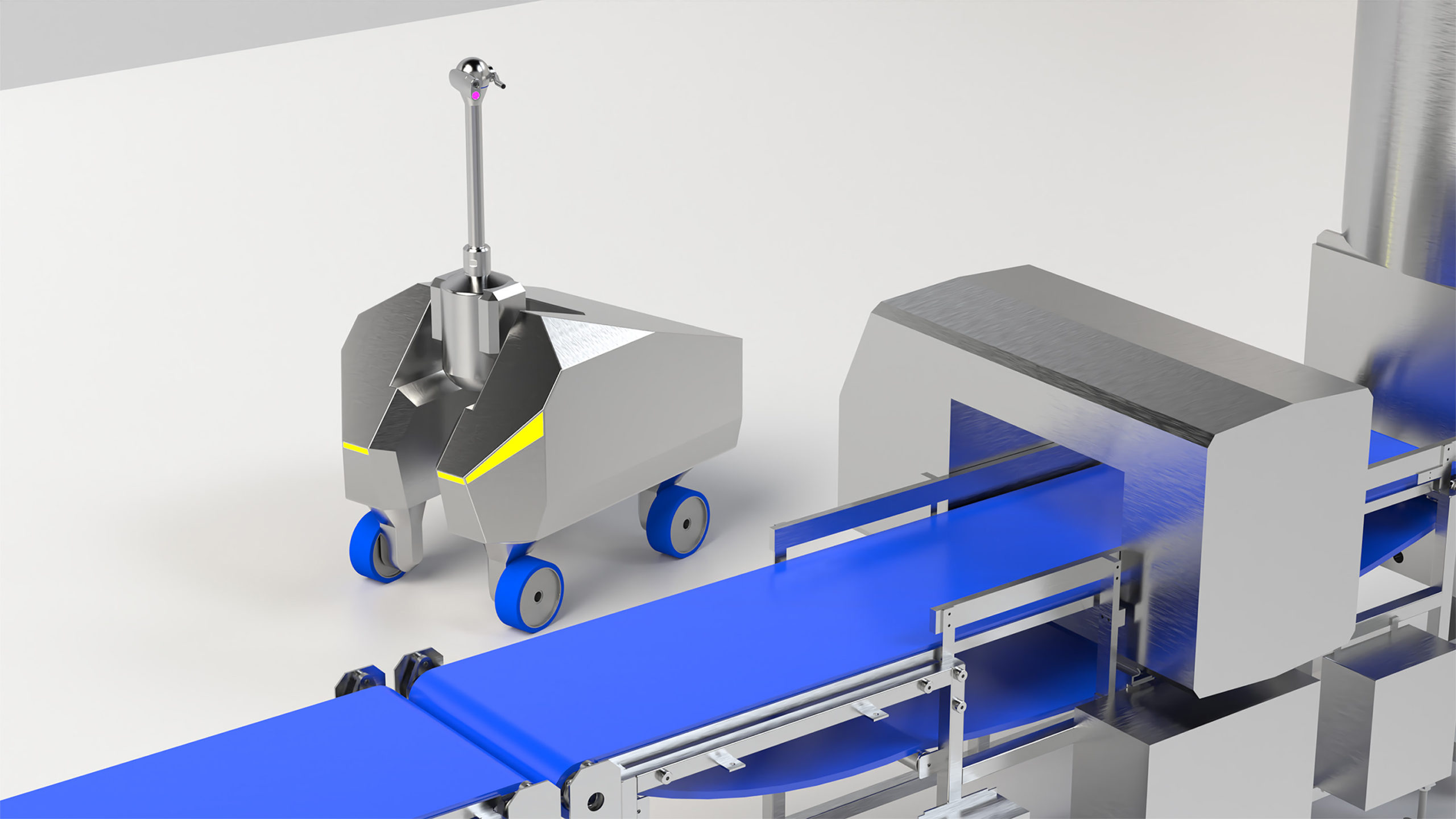

The “Exo-MCD” is a modular cleaning robot that can be deployed as an autonomous device for automatically cleaning hygiene-critical systems and production environments. Fully integrated contamination sensor technology in the MCD automatically detects the degree of contamination and means the cleaning process can be fully documented. Visitors can get a first-hand look at the potential of the “Exo-MCD” at demonstrations each day in the Robot Arena.

An innovative adaptive jet cleaner (AJC), that rotates around three axes, takes care of the cleaning. The next-level version, the “AJCsens” will also be on display at the trade fair. This adaptive jet cleaner, which operates autonomously, uses highly integrated sensor technology to enable continuous inline monitoring of the cleaning process for the first time, delivering highly efficient, need-driven cleaning.

Quality assurance - digital support for manual cleaning

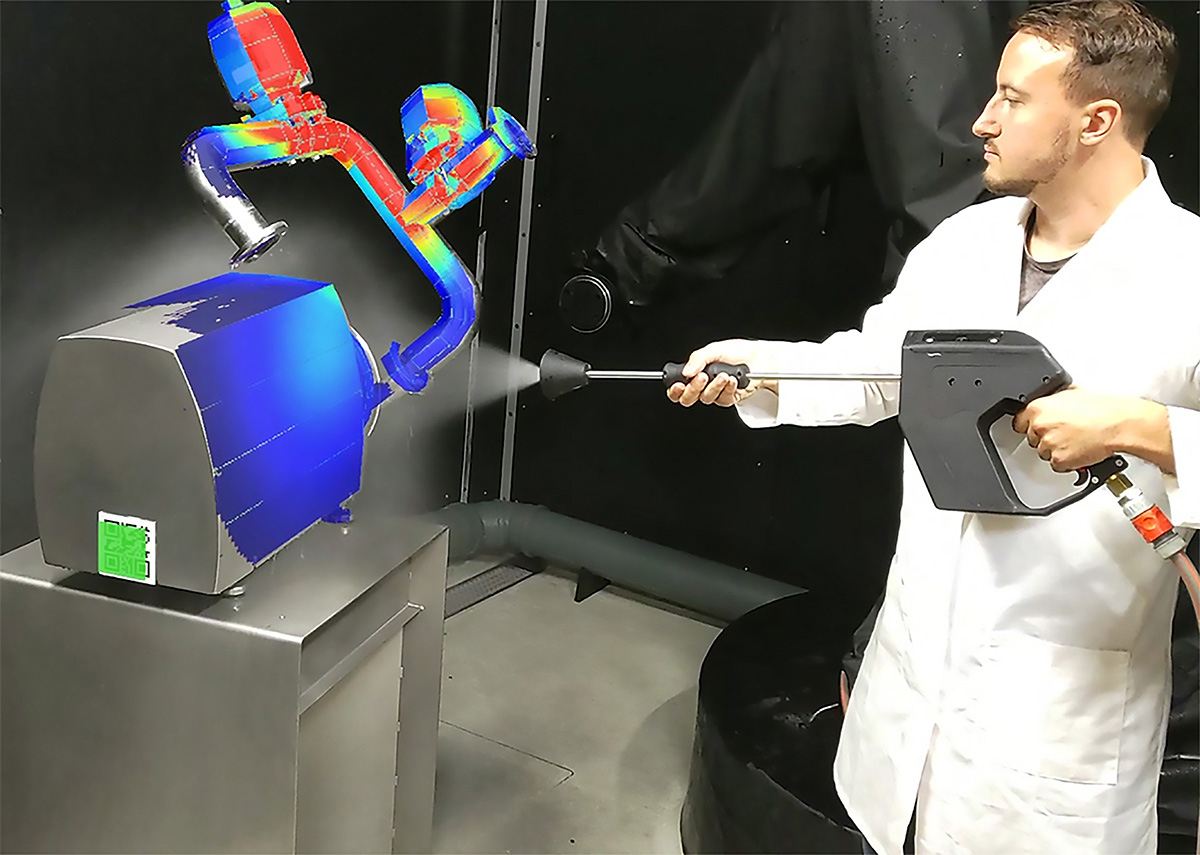

Fraunhofer IVV has developed “CleanAssist” technology to give fresh, groundbreaking impetus to manual jet-based cleaning: virtual support, digital twins and innovative sensor technology allow cleaning to be documented in full and fully automatically, and cleaning staff to be qualified swiftly and with minimal effort.

The cleaning lance is fitted with tracking sensors that visualize both cleaning performance and, for example, spray shadows. A digital twin tracks progress in the cleaning environment and displays actual cleaning progress in near real time on end devices such as, for example, a tablet or AR glasses. This means that operating personnel can physically see areas which have been missed, under-cleaned or over-cleaned, so these become a thing of the past.

Contamination detection - inline contamination sensors for a need-driven cleaning process

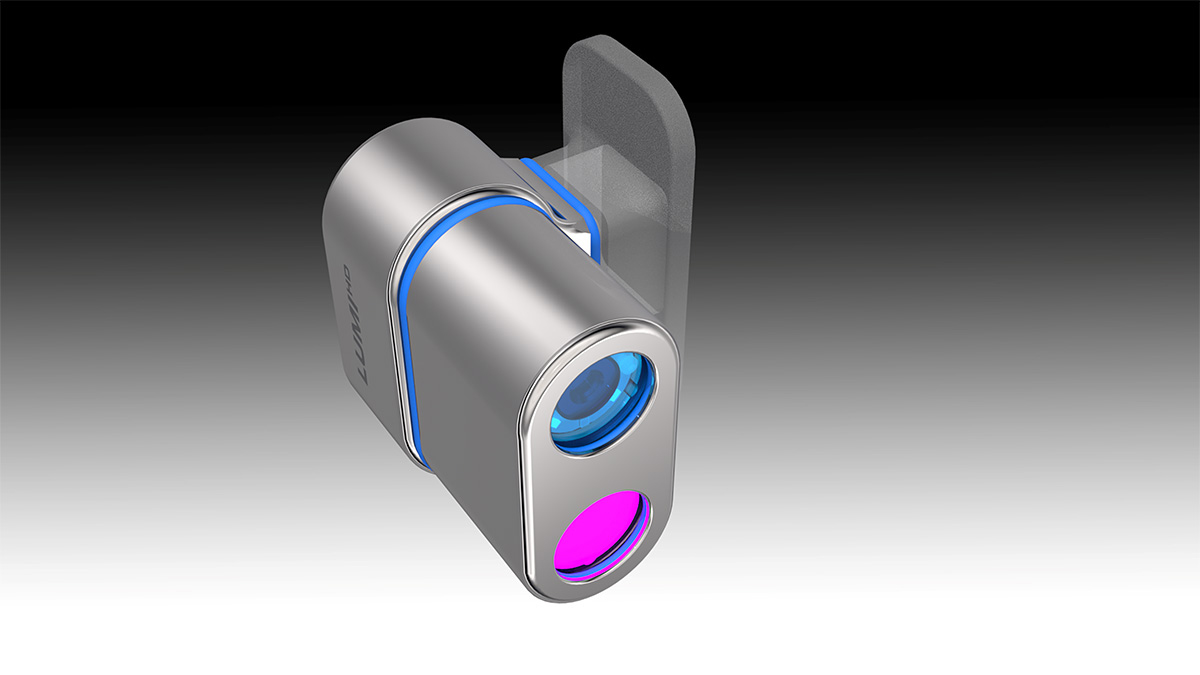

Fraunhofer IVV’s research work in the field of contamination sensors is designed to deliver powerful technology for the paradigm shift towards truly need-driven process management. It’s not just a matter of conserving cleaning resources. In view of ever more demanding challenges stemming from the growing choice of products and the related frequent changeover and cleaning processes, gaining additional production time is particularly important. We will be exhibiting two sensor systems from the CoControl range at Interclean 2024: “LumiHD” and “QCM.”

“CoControl LumiHD” is an ultra-compact yet at the same time highly sensitive optical contamination sensor for both film-like and particulate contamination. The sensor for detecting contamination uses hybrid technology to evaluate information under UV and white light excitation. This innovative combination of fluorescence properties and characteristic visible features makes it possible to reliably detect a previously unimaginable range of different types and states of contamination without the need for direct contact and over a wide area. Even non-fluorescent traces, such as burnt food, can be detected. Thanks to its hygienic design and a universal, hygienic connector, the sensor system is simple to integrate into any cleaning process. This enables continuous, automated inline control and the cleaning as well as the level of contamination to be documented.

“CoControl QCM” is an innovative sensor system for reliably detecting contamination on the walls of closed systems such as pipelines or tanks. The thickness shear mode oscillator relies on the piezoelectric effect to collect information about the contamination layer based on specific changes in vibration properties. A special evaluation algorithm can then be used to signal when the desired level of cleanliness has been achieved. This means it is now possible for the first time to measure the state of contamination directly during the fouling and cleaning cycles and to draw reliable conclusions about the actual need for cleaning and how successful it was, instead of only indirectly by evaluating the cleaning fluid. This small, compact sensor system can also be hygienically retrofitted into existing systems with little effort.

- Category

- Featured Stories