|

< Features >

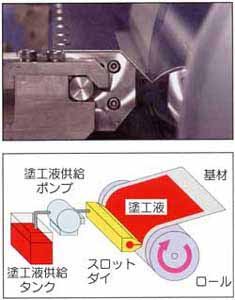

• Enables high-precision transfer of low-viscosity coating liquids used in pre-measurement coating systems by die coaters and similar equipment.

• Pump transfer units available that allow real-time monitoring of fluid transfer to die coaters and similar equipment, and ensure stable liquid transfer.

• Lack of rotating or sliding parts in liquid transfer unit means transferred liquid does not degrade, making pump ideal for UV-curable hardcoat and similar liquids.

• Lack of mechanical seals makes pump resistant to wear and eliminates leakage and admixture of contaminants.

• Liquid transfer unit features mirrored surfaces throughout to prevent contamination. Pump head can be cleaned without removing liquid transfer pipe for significantly easier maintenance.

< Applications >

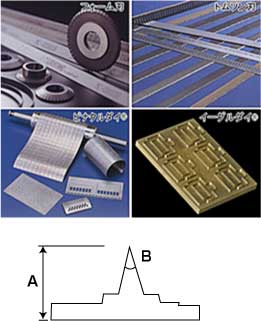

Precise thin film coating processes: Optical functional films for displays, magnetic recording media, electronic components, and electronic materials

Coating liquid mixing processes: Dispersion machine circulation and inline injections of addition agents

< Specifications >

Discharge pressure: 3.0 MPa or less

Motor: Explosion-proof specifications

Discharge volume: 0.01 to 30.0 L/minute (10 types total)

|

|

Contact Information:

Overseas sales section

2-2-14 Awajimachi, Chuo-ku, Osaka 541-0047 Japan

TEL.+81(0)6-6208-3974 FAX.+81(0)6-6208-3978

Email:

URL:http://www.tacmina.com

|

Sales Office:

Overseas sales section

2-2-14 Awajimachi, Chuo-ku, Osaka 541-0047 Japan

Products:

Metering Pumps, Metering Pumps for Disinfection, Metering Pumps for Special Applications, Related and Optional Products

|