|

Outline: Characteristics: Softal Corona & Plasma GmbH http://www.softal.de/ |

|

Contact Information: |

Sales Office: Products: |

|

Corona Surface Treatment System Characteristics: Treatment Station Softal Corona & Plasma GmbH http://www.softal.de/ |

|

Contact Information: |

Sales Office: Products: |

|

class=“qtranxs-available-languages-message qtranxs-available-languages-message-en”>Sorry, this entry is only available in class=“qtranxs-available-language-link qtranxs-available-language-link-ja” title=”日本語”>Japanese. |

Sales Office: Products: |

|

class=“qtranxs-available-languages-message qtranxs-available-languages-message-en”>Sorry, this entry is only available in class=“qtranxs-available-language-link qtranxs-available-language-link-ja” title=”日本語”>Japanese. |

Sales Office: Products: |

|

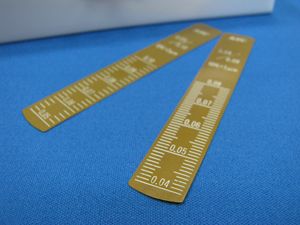

Characteristics: -Precision Performance -The material for our dies can either be magnetic (SUS630, etc.) or nonmagnetic (SUS316, etc.) |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: |

|

Contact Information: |

Sales Office: Products: |

|

class=“qtranxs-available-languages-message qtranxs-available-languages-message-en”>Sorry, this entry is only available in class=“qtranxs-available-language-link qtranxs-available-language-link-ja” title=”日本語”>Japanese. |

Sales Office: Products: |

|

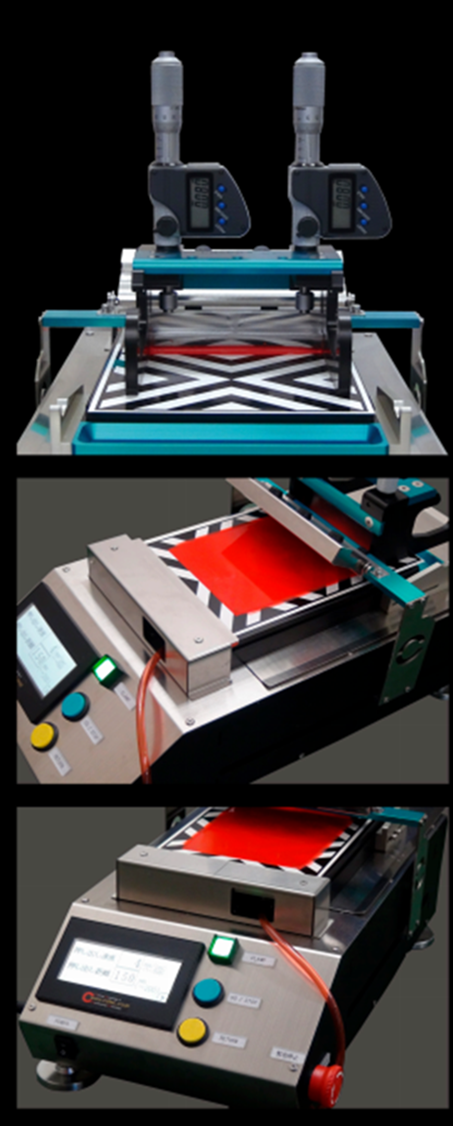

In addition to our calender forming testing facilities, which have been used by many of our customers, we have newly installed a testing research facility that allows for a range of rolling and roll press applications. Applications: Facility Configuration: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

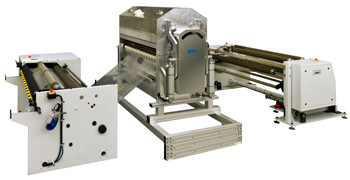

Today, the calender forming process is being reconsidered for the production of advanced films and sheets. We produce the entire calender machine, including the rollers, and have already delivered several such machines. Calender Forming Method Functions and Characteristics: *We have permanent testing and research facilities at our main plant, which we hope you take advantage of for developing your new functional materials. |

|

Contact Information: |

Sales Office: Products: |

|

We are a highly capable partner in searching for non-Japanese machines and used machinery. We offer the optimal machines and service to our customers in contributing to their future. Main Products: |

|

Contact Information: |

Sales Office: Products: |