|

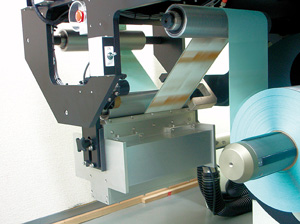

This machine is an 8-color UV flexo press for laminated tubes and film. Machine Types: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

KPG’s label inspection and slitter system inspects and slits the printed labels, and is equipped with a label counting system, missing/linked label inspection system, paper roll splicing system, and strobe system for visual inspection. Depending on customer needs, the machine can also be customized with a separatorless label rewinding system and inline inspection equipment, for example. Standard Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

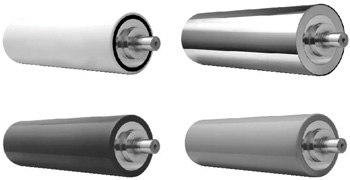

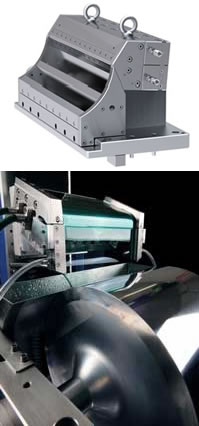

Simultaneous Multilayer Coater Our simultaneous multilayer coating technology derived from photographic sensitizer production technology is increasingly being applied in various converting locations today. Characteristics: Our simultaneous multilayer coating equipment can be used at any time for coating tests in Japan. Further, this machine can also handle thin-film slot die coating. [Coating Example: 3.5 μm wet film thickness, 23 mPas viscosity, 20 m/min substrate speed] |

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

Teknek ( ITW ) is the world leader in the manufacture and development of contact cleaning technology. |

|

Contact Information: |

Sales Office: Products: |