|

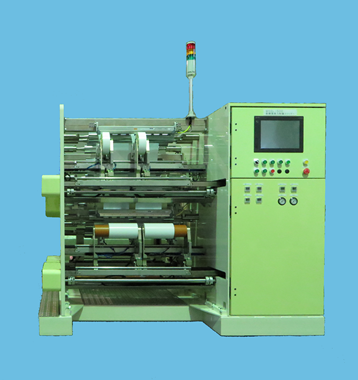

Characteristics:

(1) Bearing Type Transport System

The transport system can rotate and turn for easy loading of wagons.

(2) Unwinder Hydraulic Lift System

Eases the handling of heavy items.

(3) 2-roll Flying Cutter Comes Standard

-The razor cutter holder can be attached with one-touch.

-Lifting is operated by a handle and can be finely adjusted.

-The cutter is positioned at eye level for excellent operability.

(4) Pneumatic Horizontal Shift Single Shaft Touch-roller

The touch pressure can be accurately controlled without influence of the roll diameter.

(5) Individual Pneumatic Touch Rollers

To handle high-speed slitting of films with high thickness variation, we also use pneumatic type individual touch rollers.

(6) Close at Hand Switch

By locating the switch that locks the unwinding arm in place close at hand, we improved the operability and safety.

(7) 2-spool Edge Winding System

-Using a 2-spool system, the edges of the left and right side of the roll are wound separately.

-Reducing edge problems contributes to the increased operational efficiency of the main slitter.

Specifications:

Substrates: simple and laminated films

Substrate width: min. 500 mm to 1,200 mm

Substrate thickness: min. 12 μm to max. 100 μm

Roller face length: 1,300 mm

Unwinding diameter: max. 800 mm

Rewinding diameter: max. 500 mm

Unwinding roll weight: max. 500 kg

Core: 3” inside diameter paper core

Machine speed: max. 400 m/min

Tension: unwinding min. 50 N to max. 250 N/full width rewinding min. 30 N to max. 170 N/m

|