|

<Features> <Specifications of a test machine> |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: Applications: |

|

Contact Information: |

Sales Office: Products: |

|

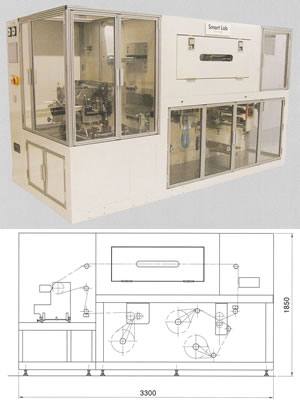

<Features> Ever since sales began in 1995, DAC ENGINEERING’s Trinity Well printing inspection systems have been based on a unique inspection technology that uses a 1-pixel unit full-color density inspection method. Given their high general-purpose applicability, these inspection systems have been adopted in an extensive range of fields, including gravure printing, high-speed rotary printing, sheet-fed offset printing, packaging printing, business form printing, and special securities printing. The latest Trinity Well model goes beyond conventional high-performance inspection to offer standard options including simultaneous color density monitoring, an image filing capability, and queuing by product type. As a system that prevents printing defects, we have designed Trinity Well to both ensure product quality and provide a powerful traceability function that tracks the defect detection data from the entire surface of every product unit. <Applications> When the high-precision 3CCD color camera line sensor unit and special lighting unit are installed on the production line, the Trinity Well printing inspection system allows for online inspection of the entire surface of every unit of a variety of printed product types. The system can also be used offline. <Specifications> Applicable Materials: film, paper, printing, aluminum laminate, etc. Minimum Resolution: X=0.17 mm (width resolution) Y=0.30 mm (travel direction resolution)/Maximum Inspection Width: 1,300 mm (when 3 line color cameras (4,000 K) and 2 inspection units are used at 300 mpm) Detectable Defects: micro-defects larger than 0.34 (X) × 0.60 (Y) mm, ink splatter, pinholes, contaminants (bugs, etc.), unprinted dots, line defects |

|

Contact Information: |

Sales Office: Products: |

|

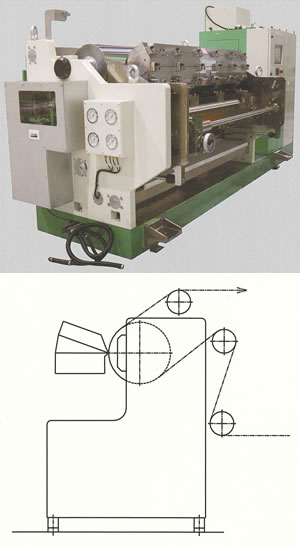

Based on the extensive experience Techno Smart has with clean coaters, we developed this miniature coating/drying system for research and development purposes. Various high-performance coater heads can be chosen from the large variety of coater head variations, which can be exchanged using the cassette change mechanism depending on the application. Further, various dryer methods can be chosen from the dryer variations. A unique nozzle exchange system allows for the dryer method to be easily chosen to meet the application. Applications: Specifications: |

| class="address" align="left" valign="top" style="width:38%;"> Contact Information: | class="eigyo" align="left" valign="top"> Sales Office: |

|

Using a multi-stage slit structure, the coater can realize simultaneous wet-on wet coat single or multiple layers. A vacuum structure comes standard, so coating at a sufficient gap clearance is possible. Our high-precision die processing technology and high-precision mounting technology, allows for a high-precision die coater using a cassette change method. Further, we can also produce special dies with internal structures that reflect the flow characteristics of the coating fluid. Applications: Specifications: |

| class="address" align="left" valign="top" style="width:38%;"> Contact Information: | class="eigyo" align="left" valign="top"> Sales Office: |

|

This steel belt casting system with unique functions was developed to meet the thickness uniformity and smoothness requirements demanded of high-precision/advanced films. Using a clean tenter device with a uniform temperature (max. 450ºC) and air speed profile as a post-film forming thermal treatment, the system is suited to the manufacture of high-value films and sheets. Applications: Specifications: |

| class="address" align="left" valign="top" style="width:38%;"> Contact Information: | class="eigyo" align="left" valign="top"> Sales Office: |

|

Product Name: Utility Power Super Steamer (UPSS) Applications: Specifications: Steam Pressure: 0.15 MPa Power Input: 3 phase 50/60 Hz 200/220 V |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Applications: Specifications:

|

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Compared with other types of heated rolls, this type realizes major energy savings. Energy saving, clean, low-maintenance -Clean and maintenance free Applications Specifications: |

|

Contact Information: |

Sales Office: Products: |