|

Characteristics: Applications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Able to laminate of metal foil in high-temperature regions. As an antioxidation measure for metal foil, the laminating unit uses a high-concentration nitrogen gas purge booth. Applications: Flexible copper laminate Usage: Temperature: R≦4ºC Max. 400ºC Speed: 1 to 10 m/min Substrate Width: 600 mm |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Application: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Having an internal gear pump of the same width as the die, the GPD allows for stable high-speed coating of high-viscosity fluids in the width direction. The die has an open structure that allows for easy cleaning. The coating lip can either use a rod type that reduces streaking or an edge type that produces a sharp coating surface. We have two 300 mm width permanent testing machines available, one with a dryer unit and one with a UV curing unit. The photo is of the dryer unit testing machine. Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Applications: Specifications (2 types):

Options include a roller conveyer for disposal, automatic disposal device, dancer control mechanism for speed following, and a special surface treatment for adhesive film reels. Options are available for other line structures. | |||||||||||||||||||||

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Capatch is a Netherlands based Steinhart low-cost disposable, sticker type cell volume measuring system that rapidly, easily, and consistently measures cell volume. The system allows cell volumes to be measured while the roll is mounted on the printing machine. Principle: Low Volume (green): 2 to 7 cc/m2 |

|

Contact Information: |

Sales Office: Products: |

|

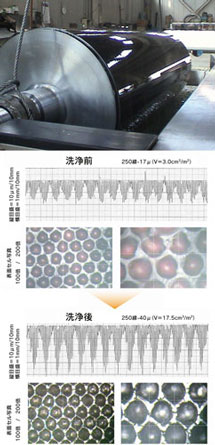

New Production: Our final surface grinding is unique. We have also installed three UK based Alphasonics cleaning machines, with which we have cleaned more than 20,000 rolls. Using these machines we can restore ceramic and chrome rolls to new by removing various types of clogged ink. In more than 20 years of operations, we have never damaged a roll. We measure the cell shape, depth, and volume before and after cleaning to manage the customer’s rolls. |

|

Contact Information: |

Sales Office: Products: |

|

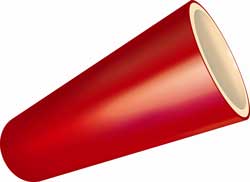

Through a 2007 technological collaboration between ROLLTECH and POLYWEST (Germany), with its top share in Japan, we established POLYWEST JAPAN in beginning the production and sale of plastic sleeves domestically in International. As such, we are able to reduce delivery times and provide rapid response aftercare. New Material Sleeve “RUBIN” Compared to conventional sleeves, RUBIN has a more durable surface, which reduces bouncing during printing and improves print quality. RUBIN is difficult to cut and has excellent solvent resistance. Characteristics: -Sleeve wall thickness can be freely set between 1 and 72 mm (equivalent to a maximum printing repeat length of 440 mm) -Mounting and removal of the sleeve is conducted by simply blowing pressurized air with a load of 5 to 6 Kg/cm2 from the edge face of the air cylinder, so is extremely easy and improves work speed. When the air pressure is removed, the sleeve locks in place so that there is no misalignment, rotation, or slip during printing. -The sleeve can be attached to the cylinder with cushion tape and double-sided tape to greatly improve the printing efficiency of used sleeves. -Rubber mounting can be conducted as easily as with steel rolls, so can be used with various rolls, including flexo printing solid sleeves and gravure printing/coating impression rolls. -The inner diameter of the sleeve and the air cylinder have a straight structure. |

|

Contact Information: |

Sales Office: Products: |