Production Results:

Film Thickness: 1 to 350 μm

Film Width: 8,400 mm (max.)

Speed: 500 m/min (max.)

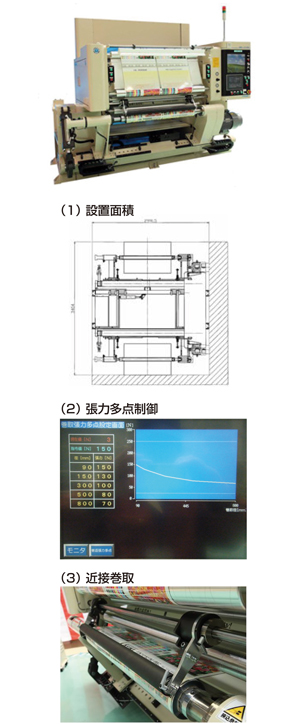

Hyper-bending Contact Roll

The ideal nip is realized by adjusting deflection caused by the weight of the roll and adjusting surface-pressure bending, which allows for winding of high-quality products.

Charging Device and Belt Wrapper

A wrapping system and charging device allow thick films to be wound on a new core without problem.

Film Pass Nip Roll System

This system provides the optimal film pass for stably transporting the film from the takeup system to the winder. The system is equipped with a nip roll.

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Specifications: Other: *Confirm your application on our test machines. |

|

Contact Information: |

Sales Office: Products: |

|

Applications: Specifications: Installations: |

|

Contact Information: |

Sales Office: Products: |

|

Characteristics: Consistent Registration Precision Significantly Reduced Loss High Operational Rate Water-based Gravure Printing, Process Printing |

|

Contact Information: |

Sales Office: Products: |

|

The quality of a coating product requires high-quality coating resulting from a high-precision coating head. At the same time, quality also relies on the stability and efficiency of the curing process, in other words the post-coating drying process. For this reason, we consider the drying process critical to the determination of coating quality. |

|

Contact Information: |

Sales Office: Products: |

|

The demand for lithium-ion batteries, including those for automobiles and stationary applications, is expanding. We have sold more than 250 lithium-ion electrode coaters, and manufacture and supply equipment that can handle the high-precision, high-speed coating demands required to meet the needs of the market. Our intermittent coating systems, required for electrode coaters, can be equipped with comma type coating heads for test and pilot lines that coat small volumes, as well as die coating heads designed for high-volume production. Our dedicated intermittent coating system realizes high-precision, high-speed, stable coating in intermittent die coating. We also have an electrode coater pilot line at our Technicum facility, which allows for pattern coating tests, including intermittent and stripe coating. As such, we hope you coat and evaluate your electrode slurries. Applications: Battery electrode coating (lithium-ion batteries, super capacitors, etc.) Specifications: Machine Speed: 30 to 100 m/min Roller Width: 400 to 1,500 mm |

|

Contact Information: |

Sales Office: Products: |

|

Developed based on our experience and technology accumulated through large-scale production machines, the Multicoated Series is a small, continuous coating machine. It is designed to evaluate coatings and products using a variety of coating methods, but also has a small-scale production function aimed at scaling up production to production machines, short-run production, and prototype production, for which it has been highly accepted. This series has already received several hundred orders since its development, but we also offer customized models to meet customer needs. Moreover, the coating unit is designed to be modular so that it can handle all coating methods. In fact, we have installed a Multicoater with this mechanism in our Technical test facility. In this way, we offer this machine as a development and production line for high-precision, high-value oriented products. Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

The “Supply Type Doctor Blade Gravure Coater” is based on our gravure coating technology and reduced problems with open-type systems. Applications: Specifications: |

|

Contact Information: |

Sales Office: Products: |