|

-MEITACK Applications: |

|

Contact Information: |

Sales Office: Products: |

|

|

Contact Information: |

Sales Office: Products: |

|

The Light Hammer 10 UV curing device brings all of the benefits of microwave-powered UV lamps to a ten-inch (254 mm) system. Using DC power supply irradiation, the system is able to form cured films with more uniform molecule sizes than AC power supply UV lamps. Characteristics: Applications: Specifications: As a pioneer in UV curing devices and process technology, Fusion UV Systems is a leading global supplier. |

|

Contact Information: |

Sales Office: Products: |

|

This film forming machine coats in a vacuum using a roll-to-roll system. Characteristics: Specifications: |

|

Contact Information: |

Sales Office: Products: |

|

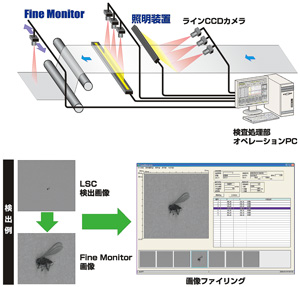

Our LSC-4000 Series Advanced Defect Inspection System is a top ranked inspection system often adopted in the optical and functional film fields. Characteristics: “Fine Monitor”: Defect Imaging Monitoring Unit |

|

Contact Information: |

Sales Office: Products: |

|

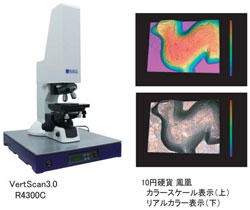

Summary: Specifications: |

|

Contact Information: |

Sales Office: Products: |